Solder Inspection Services

Automatic Optical InspectionOver the last 10 years or so Automatic Optical Inspection AOI of both solder joints and component placement has developed and grown to become a tool of real value for manufacturers.

Beset by issues of false failures, or worse, false passes, whilst providing some benefits these machines were treated with a degree of scepticism, and they were very hard to programme.

This is no longer the case.

AOI can be programmed directly from the original CAD files, so that programme generation is a very fast activity. Yields have improved enormously to the extent that the results can now almost always be relied upon with confidence, and solder joints even for lead free joints are reliable.

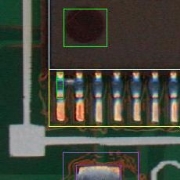

The machine is therefore used to examine solder joints for visual integrity, skewed or misplaced parts, missing parts, tombstoned parts and other potential process induced problems.

BGA Inspection

For BGA inspection this is rather more difficult because it is not possible to see under the device and look at each ball joint. Not possible, that is, unless you have an ErsaScope.

This system uses a split prism to look through the very small space under a BGA along both the horizontal and vertical rows between the underside of the BGA and the bare board and to focus all the way along the array to see, in the matrix, if there are any mis-shapen or missing reflowed balls of solder.

Visit the Prima Electronic Services Ltd website for more information on Solder Inspection Services