Overcoming Vibration Testing Challenges: A Success Story of Collaboration

06-10-2023

Protean Electric, a global leader in in-wheel motor (IWM) technology, is driving innovation in passenger cars, light commercial vehicles, and future transport solutions. Their in-wheel motors (IWMs) are meticulously engineered to deliver exceptional performance, efficiency, and sustainability across various applications. Notably, these motors offer a spectrum of advantages, from granting original equipment manufacturers (OEMs) creative freedom to enhancing the driving experience for consumers by creating more interior space and accommodating additional battery storage for increased range.

Challenges Ignite Innovation

However, pioneering such groundbreaking technology is not without its challenges. In-wheel motors, nestled within the wheel itself, face a harsh operational environment and external forces. Road conditions subject these motors to heightened levels of shock and vibration, necessitating rigorous durability testing.

Protean Electric, in their quest to overcome these testing challenges and enhance their product development cycle, embarked on a partnership with CentraTEQ. CentraTEQ is renowned for its expertise in crafting custom-designed fixtures and vibration testing solutions.

A Collaborative Approach

Protean Electric's objective was crystal clear: the development of a bespoke fixture capable of supporting the test item during vibration testing, all within defined parameters. The fixture had to exhibit stability across multiple axes, accommodate a wide frequency bandwidth, and withstand the rigours of intense acceleration and temperature fluctuations.

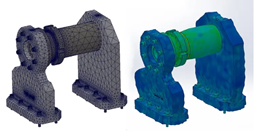

Through a closely-knit collaboration with Protean Electric's engineering team, CentraTEQ engineered a specialised "H" fixture. This fixture's symmetrical support structure effectively minimised unwanted vibrations, while its thoughtful design allowed for the seamless rotation of the payload without requiring disassembly.

Success Through Partnership

Protean Electric's vibration tests, conducted using the custom fixture, were a resounding success. Mark McDonnell, Protean's Product Validation Manager, lauded the partnership, highlighting the consummate professionalism and technical prowess of the CentraTEQ team.

This successful collaboration underscores the pivotal role of tailored fixture design in vibration testing. It accentuates the significance of partnering with experienced experts who possess an in-depth understanding of vibration test fixture design, encompassing the intricate properties of the fixture materials, their resonant frequencies, and their potential impact on testing outcomes. Together, Protean Electric and CentraTEQ are setting new benchmarks in the realm of in-wheel motor technology through their commitment to innovation and precision testing.