Multi-Axis Vibration Testing: A Smarter Approach to Real-World Simulation

Products rarely experience vibration along a single axis. Vehicles, aircraft, industrial machinery and electronics are subjected to complex, simultaneous inputs from multiple directions. Multi-axis vibration testing replicates these conditions more accurately than traditional single-axis methods, enabling engineers to assess durability, performance and reliability under true operational stress.

What is multi-axis vibration testing?

Multi-axis testing excites a specimen along two or more axes at the same time, typically using electrodynamic or hydraulic shakers arranged orthogonally or integrated within a single multi-axis platform. While single-axis testing drives the X, Y or Z direction sequentially, multi-axis testing can excite multiple directions concurrently—often across six degrees of freedom (6DoF): three translational (X, Y, Z) and three rotational (pitch, roll, yaw). This exposes the article under test to combined loading that better represents real service environments.

Why simulate multiple axes?

Single-axis tests are valuable, but they can miss cross-axis coupling—the way motion in one direction influences another. In practice, vibrations interact:

-

In vehicles, engine excitation combines with road-induced inputs along all three axes.

-

Aerospace structures see simultaneous thrust, aerodynamic and structural effects.

-

Consumer products encounter complex, random inputs from several directions during handling and use.

Multi-axis testing therefore provides a more realistic picture of structural response, component fatigue and potential failure modes.

System configurations

-

Multiple single-axis shakers (orthogonal): Several shakers mounted at right angles drive each axis. Highly flexible, but requires sophisticated synchronisation and control.

-

Tri-axis shaker systems: An integrated base with three orthogonal shakers for compact, simultaneous excitation—ideal for smaller payloads and high precision.

-

5DoF and 6DoF tables: Platforms with multiple actuators generating controlled translational and rotational motion. Full 6DoF hexapod-style systems offer complete control for the highest-fidelity simulations.

Control and measurement

Synchronising several axes adds complexity. Closed-loop, multi-input multi-output (MIMO) controllers must coordinate phase, amplitude and frequency content across all channels to maintain realistic spectra and avoid over- or under-testing. Measurement systems need multi-channel acquisition, high sampling rates and tools such as cross-spectral density and coherence analyses to evaluate inter-axis interactions.

UK engineers can access a broad range of multi-axis solutions through CentraTEQ, backed by decades of experience deploying advanced vibration systems in automotive, aerospace and electronics labs.

Applications

-

Automotive: Powertrain, suspension and ECUs under combined road and engine inputs.

-

Aerospace & defence: Avionics, satellites and weapon systems across launch and flight profiles.

-

Electronics: PCBs and enclosures subject to multi-directional vibration and transport shock.

-

Energy & industrial: Turbines, pumps and heavy machinery requiring fatigue and resonance studies.

Multi-axis solutions from CentraTEQ

-

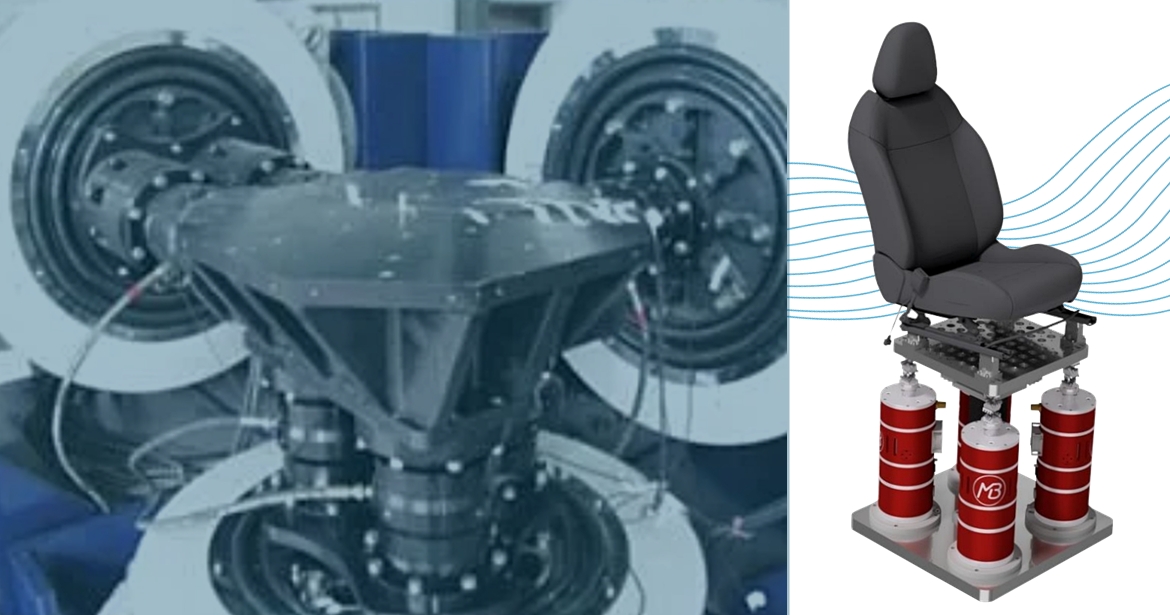

MB Dynamics VPR (Vertical, Pitch, Roll): A 5DoF system delivering simultaneous vertical, pitch and roll motion. It is a high-precision dynamic motion and vibration simulator suited to coordinated vertical/rotational inputs rather than the very high forces of large multi-axis tables. Typical uses include dynamic simulation of vehicle and aircraft motion, validation of sensors, cameras and navigation systems, testing of gimbals and image stabilisation, vibration and endurance work, Buzz, Squeak & Rattle assessments, seat and ride-comfort studies and transport or packaging simulations where realistic coupled motion is critical.

-

ETS Solutions MET Series: Multi-axis shakers engineered for simultaneous three-axis testing across a wide frequency range with high acceleration and long stroke, supporting dual-, tri- or multi-degree-of-freedom sine, random and shock tests.

CentraTEQ provides expert guidance on fixture design, control strategies and best practice to ensure tests are reliable, repeatable and representative of real operating conditions.

Visit the CentraTEQ Ltd website for more information on Multi-Axis Vibration Testing: A Smarter Approach to Real-World Simulation