Vibration Testing for the Next Generation of EVs

Electric vehicles are redefining automotive engineering, introducing new powertrain architectures, heavier subassemblies, and tightly integrated systems. The propulsion may be electric, but vibration challenges remain firmly physical.

As EV designs evolve, so do testing demands. Battery packs, inverters, drive units, and power electronics must endure years of real-world use, all under regulatory scrutiny and high customer expectations for refinement. Vibration testing is central to proving that performance.

The fundamentals of vibration testing haven’t changed, but the systems under test—and the profiles they must withstand—are markedly more complex.

Vibration challenges in EVs

With the internal combustion engine gone, so too is its masking noise and mechanical vibration. In the near-silent cabin of an EV, any rattle, buzz, or hum is more obvious. Meanwhile, many EV components—especially battery packs—are heavier, more rigid, and more integrated than their ICE-era equivalents. Mounted low in the chassis, batteries experience torsional stresses, road-induced vibration, and mechanical shock over long lifetimes. Electric drive units and onboard power systems add complexity, with electronics highly sensitive to dynamic inputs and thermal effects.

What’s driving the shift in testing requirements?

Several trends are raising the bar:

-

Battery durability and safety: Lithium-ion packs must demonstrate mechanical robustness through years of charge/discharge cycles and road use.

-

Heavier integrated components: Compact but weighty drive units demand higher loads and more complex multi-axis testing.

-

New regulations: Standards such as UN ECE R100 and ISO 12405 impose stringent vibration and shock profiles, particularly for batteries.

-

Extended endurance expectations: With fewer mechanical wear points, EVs rely on long-term vibration and thermal robustness.

Test teams therefore need systems that simulate conditions precisely, capturing interactions between structure, temperature, and dynamic forces across the vehicle lifecycle.

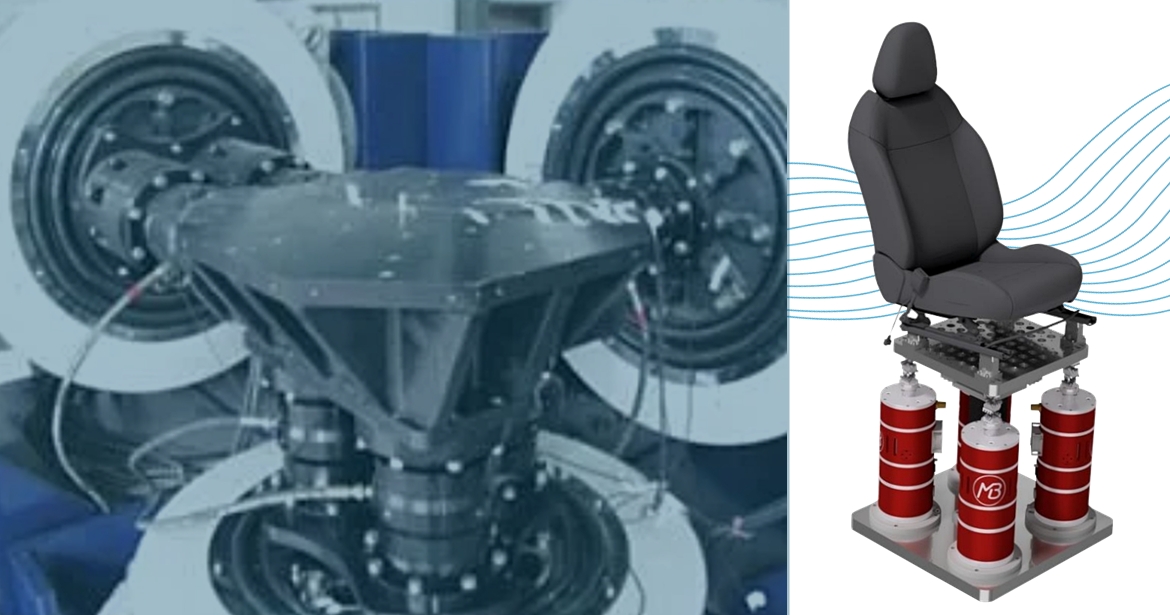

Electrodynamic shakers

Electrodynamic shaker systems sit at the heart of EV vibration testing. Their controlled, repeatable profiles across wide frequency ranges make them essential in R&D and production. Typical EV requirements include:

-

High acceleration to simulate shock events and extended road exposure

-

Long stroke for packaging and underbody component tests

-

Multi-axis configurations to replicate compound load paths

-

Integrated environments combining vibration with thermal or electrical cycling

From sine sweep resonance on an inverter module to endurance testing of a complete battery pack, shakers must offer high reliability, flexible control, and be backed by local expertise and responsive support.

Local expertise. Proven systems.

CentraTEQ is the exclusive UK supplier of ETS Solutions electrodynamic shaker systems—trusted by EV developers and Tier 1 suppliers for performance, controllability, and long-term reliability. The ETS range covers:

-

Low-force systems for electronics and subcomponents

-

Medium and high-force systems for drivetrains, battery packs, and structural assemblies

-

Long-stroke and multi-axis configurations for complex, real-world simulations

CentraTEQ delivers more than hardware: slip tables, power amplifiers, head expanders, vibration control systems, fixtures, and long-term service and applications support.

Powering the future

Vibration testing rarely makes headlines—but it enables them. EVs must meet performance and safety targets while delivering quiet, refined operation over long lifespans. Whether you’re verifying battery pack endurance, validating motor assemblies, or qualifying high-voltage electronics, the right shaker system can be the difference between confidence and compromise. With ETS Solutions systems supported by CentraTEQ in the UK, your test environment can be every bit as advanced as the technology you’re validating.

Visit the CentraTEQ Ltd website for more information on Vibration Testing for the Next Generation of EVs